- Home

- Logifleet Blog

- Your Construction Site’s Biggest Leak Isn’t What You Think

Your Construction Site’s Biggest Leak Isn’t What You Think

Picture this: it’s the end of the day, and everything appears to be on track. Crews are wrapping up, materials are accounted for, and progress reports look good. But two excavators have been sitting idle for hours, a delivery van never moved after lunch, and half a toolbox didn’t make it back from the site.

No alarms went off. No one noticed.

That’s how profit quietly slips away on construction projects; not through big mistakes, but through small, untracked inefficiencies.

Most construction firms track materials, fuel, and labour cost carefully - but vehicles and tools often slip through the cracks. Without real-time visibility, inefficiencies pile up. Machines sit unused, tools get lost, and project timelines stretch. By the time it’s spotted, the damage to margins is already done.

In this blog, we’ll break down how these inefficiencies affect your bottom line; and how construction equipment GPS tracking helps construction leaders regain control, reduce waste, and improve profitability.

The topic in short:

- Untracked vehicles and tools quietly drain profitability through idle time, loss, and inefficiency.

- Many construction firms still depend on manual logs and disconnected systems, leaving major visibility gaps.

- These hidden costs can stack up to tens or even hundreds of thousands of Francs each year.

- Automating asset tracking with construction equipment GPS tracking helps reduce waste and improve utilisation.

- Greater visibility means higher ROI, improved scheduling, fewer losses, and more reliable project delivery.

Let’s take a closer look at it.

What are the Hidden Costs in Construction Fleet and Equipment Management?

We all know the big-ticket items on a construction site: steel, cement, wages, and fuel. Those get tracked, reported, and budgeted for. But what about the silent losses that slip by unnoticed?

A van parked for hours at one site. Excavators sitting idle while waiting for work. Tools that go missing between projects. Each of these might seem small, but together, they drain productivity and profitability.

What makes these losses particularly dangerous is their invisibility. They don’t show up as separate line items in reports. Instead, they accumulate quietly, reducing margins and operational flexibility. Real-time visibility turns these unknowns into data you can act on before they turn into financial leaks.

How Much Do Untracked Construction Assets Really Cost Your Business?

It’s easy to shrug off a few idle machines or missing tools. But when you zoom out, those “small” losses compound quickly.

- Idle Vehicles and Underutilised Equipment: Take an excavator sitting idle for four hours a day, five days a week - that’s 20 hours of lost productivity. Add in depreciation, fuel, and insurance, and that machine alone could cost your business hundreds of Francs a month.

- Tool Loss and Theft: On active sites, tools go missing all the time - sometimes misplaced, sometimes stolen. Every lost drill or hammer slows work while teams scramble for replacements. It’s not just a hassle; it’s expensive. In fact, according to Forbes, losses in the industry often exceed $1 billion annually. Even a tiny fraction of that industry figure can translate into thousands in annual losses for a single company.

- Administrative Inefficiencies: Keeping track of assets manually with logs and spreadsheets is not just time-consuming; it’s also prone to mistakes. This eats up your team’s time, drives up labour costs, and can lead to decisions based on inaccurate information.

- Compliance and Safety Risks: Without visibility, unauthorised equipment use, missed maintenance, or safety oversights can slip through the cracks; exposing your business to downtime, penalties, and reputational damage.

What Everyday Inefficiencies Drain Construction Budgets?

Even with the best intentions, many construction firms struggle to achieve full operational visibility. Here’s why:

- Manual Processes: Traditional spreadsheets and paper-based logs still dominate, leaving room for inaccuracies and delays.

- Fragmented Data Systems: Information about vehicles, tools, and personnel often lives in separate systems that don’t talk to each other.

- Operational Complexity: With multiple sites, subcontractors, and shared assets, keeping track of who’s using what and where is a daily challenge.

These gaps make it hard to form a complete picture of operations. The lack of integration is not just an administrative inconvenience; it’s a source of hidden cost. Without consolidated data, construction leaders can’t make informed decisions about asset deployment, procurement, or maintenance planning.

How Can You Quantify Hidden Costs in Construction Operations?

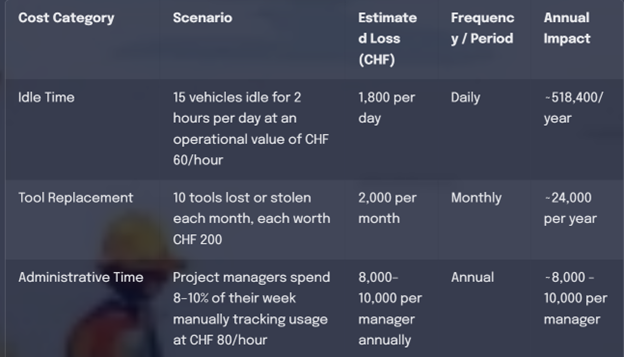

Translating inefficiencies into numbers reveals just how costly they are. Idle time, tool loss, and manual tracking can quietly add up to hundreds of thousands of Francs in losses each year; spread across projects, teams, and sites.

Gaining Better Visibility on Your Assets

Manually managing vehicles, equipment, and tools can be time-consuming and prone to errors. Automating asset tracking helps eliminate these blind spots.

The right construction equipment GPS tracking system shows where assets are, how they’re being used, and when maintenance is due.

With that visibility, project managers can make faster, smarter decisions; reducing waste, optimising schedules, and improving resource utilisation.

A reliable construction fleet management solution brings all this data together in one place, freeing teams to focus on what actually drives project success.

Logifleet’s advanced tracking ecosystem gives construction businesses the tools to eliminate uncertainty, streamline operations, and reclaim lost value.

Operational Benefits of Automated Asset Visibility

Automated visibility doesn’t just cut costs - it transforms how construction teams operate:

- Smarter Scheduling: Live location data enables project managers to allocate assets dynamically based on live site needs.

- Improved Accountability: Teams are more responsible when their activities are visible and measurable.

- Accurate Billing and Reporting: Automated logs eliminate manual errors and support transparent client billing.

- Proactive Maintenance: Predictive tracking ensures timely servicing, reducing downtime and extending equipment lifespan.

- Enhanced Safety and Compliance: Real-time monitoring prevents unauthorised use and supports regulatory compliance.

Wrapping Up: Visibility Isn’t a Luxury - It’s a Profit Strategy

In construction, every idle hour, misplaced tool, or unplanned delay chips away at profitability. The problem isn’t effort - it’s visibility. You can’t optimise what you can’t see.

By adopting a unified construction fleet management solution, businesses can turn blind spots into insights. Real-time tracking helps you see where every vehicle and tool is, how often they’re used, and what it’s really costing you when they’re not.

The result is less waste, fewer surprises, and more predictable margins.

If you’re ready to uncover where your money’s really going, and start taking control of it, now’s the time to explore how construction equipment GPS tracking can help.

Ready to Learn How Construction Visibility Helps You Save Hidden Costs?

To see how Logifleet can help you spot hidden costs and transform them into measurable results within 90 days, schedule a personalised demo.

Frequently Asked Questions

- What is constructionequipmentGPS tracking, and why is it important?

Construction equipment GPS tracking involves using satellite-enabled devices to monitor the real-time location, usage, and performance of vehicles and tools across job sites. It helps project managers and business owners reduce idle time, prevent theft, and ensure efficient utilisation of resources, ultimately improving profitability and project timelines.

- How does a construction fleet management solution help improve operational efficiency?

A construction fleet management solution consolidates all vehicle and equipment data into one centralised platform. By visualising where every asset is located and how it’s being used, managers can optimise scheduling, reduce downtime, and eliminate duplicate rentals. This leads to faster project execution, improved asset utilisation, and reduced overhead costs.

- What kind of ROI can I expect from implementing GPS fleet tracking software?

The return on investment (ROI) from GPS fleet tracking software depends on fleet size and site complexity. On average, construction companies experience:

- Up to 30% reduction in idle time

- 15 - 25% savings in fuel costs

- Significant decrease in tool replacement and rental expenses

These efficiencies compound over time, delivering a measurable impact on annual profitability.

- Can GPS tracking software and hardware help preventtooland equipment theft?

Yes. Modern GPS tracking software and hardware solutions like Logifleet’s Tool Connect or Mini Tool Connect provide location data and movement alerts. This allows managers to immediately detect unauthorised use or relocation of assets, minimising theft risk and reducing recurring replacement costs.

- Is construction equipment GPS tracking difficult to implement across multiple job sites?

Not at all. Logifleet’s tracking solutions are designed for scalability and ease of deployment. Whether you’re managing a single project or dozens of active sites, construction equipment GPS tracking can be seamlessly integrated with existing systems, allowing your team to start monitoring assets and improving visibility in a matter of days.

- What data can I access usingLogifleet’sconstruction tracking solutions?

Logifleet’s Vehicle Connect and Mini Tool and Tool Connect products provide detailed insights such as:

- Location and asset movement history

- Engine hours and idle time

- Maintenance schedules and usage logs

- Site-level performance analytics

This visibility helps you make informed decisions, reduce manual work, and enhance project accountability.

En Budron H9

CH-1052 Le Mont s / Lausanne

T +41 21 651 06 51

Merkurstrasse 25

CH-8400 Winterthur

T +41 71 277 52 47