One Platform for Every Construction Delivery - Maximizing Fleet Efficiency in Real-Time

In construction logistics, every kilometer counts. Whether it’s trucks, dumpsters, heavy equipment, or concrete mixers, empty runs and poor coordination cost money, time, and client trust. Rising fuel prices, new regulations such as the Swiss LSVA III tax, and tight construction deadlines leave no margin for inefficiency.

With Logifleet360°, dispatchers and managers finally have one screen that shows vehicles, jobs, and sites in real time - making it possible to plan smarter, cut costs, and maximize every asset.

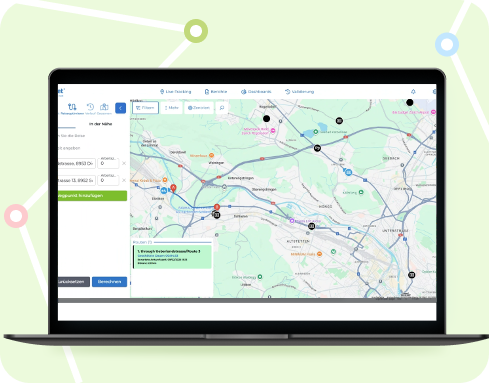

The Fastest Way To Assist

Urgent Requests. Instant Answers.

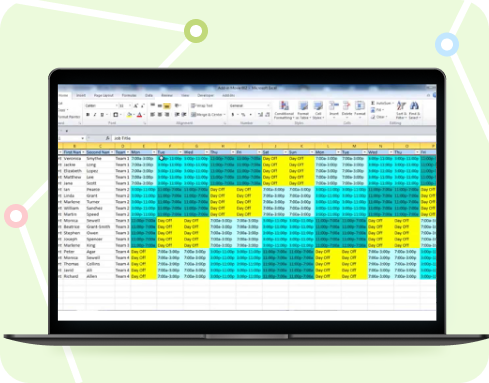

Nathalie, a logistics planner at a dumpster rental company, used to juggle Excel schedules, endless driver phone calls, and urgent emails from site managers. Every time a site requested a new dumpster, she had to piece together information manually - leading to delays, errors, and plenty of empty truck runs.

With Logifleet360°, Nathalie sees everything on a single screen:

- where available dumpsters are,

- which drivers are nearby,

- and which construction site has the next urgent request.

01

Avoiding Empty Trips

Instead of sending a truck back to the depot, Nathalie can reassign a dumpster returning from one site directly to another mission. This means fewer wasted kilometers, faster response times, and more satisfied clients.

Just like Nathalie avoids empty trips with dumpsters, Sandro faces a similar challenge with heavy machinery - where the right timing and vehicle choice can make or break a project.

02

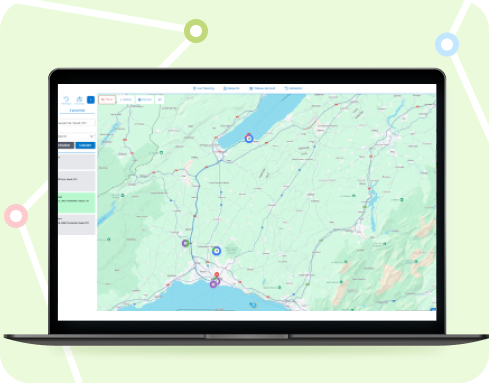

Right Equipment, Right Site, Right Time

Sandro manages the transport of excavators, compactors, and other heavy machinery. Before Logifleet, he relied on paper schedules and calls from site managers to know which machines needed to be moved. That often meant delays, double-bookings, or trucks showing up with the wrong capacity.

Now, with Logifleet360° he can see in real time:

- which machines are active or idle,

- which construction sites are involved (with GPS precision),

- and which trucks are available with their current load capacity.

03

Smarter Planning. Fewer Delays.

With this visibility, Sandro dynamically assigns the right truck for the right load. Equipment arrives on time, unnecessary transports are avoided, and costly site delays become a thing of the past.

While Sandro uses real-time planning to move machinery efficiently, Karim applies the same principles to something even more time-critical: concrete deliveries.

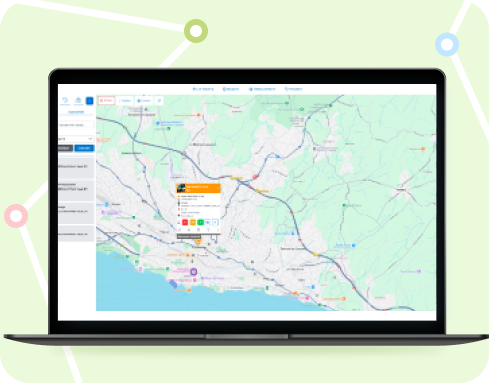

04

Deliver More. Wait Less.

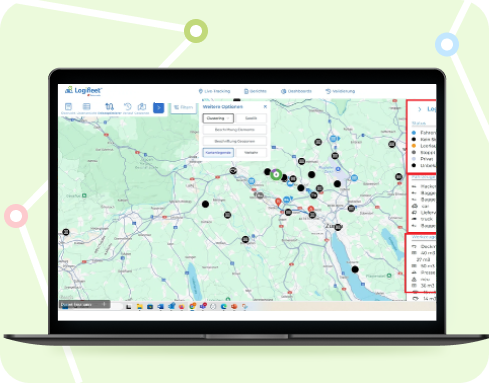

Karim oversees a fleet of concrete mixer trucks. His biggest challenge? Coordination. Drivers would finish a pour and wait idly until he contacted them with their next job - wasting time and reducing the number of deliveries possible per day.

With Logifleet360°, Karim anticipates the next need in real time:

- which truck has completed its delivery,

- which site requires the next pour,

- and which route is fastest, including live traffic data.

05

Precision and Productivity

Now, drivers are reassigned the moment they’re available. Mixers spend less time waiting, more time delivering, and customers benefit from accurate ETAs and on-time pours.

And whether it’s dumpsters, machinery, or mixers, the same efficiency challenge also applies to standard freight deliveries - which David solves every day with Logifleet.

06

Turning Every Kilometer into Profit

David is a dispatcher managing trucks that handle daily deliveries. One recurring issue was clear: trucks returning empty after drop-offs, even though there were loads nearby. Empty kilometers meant lost revenue and higher operating costs.

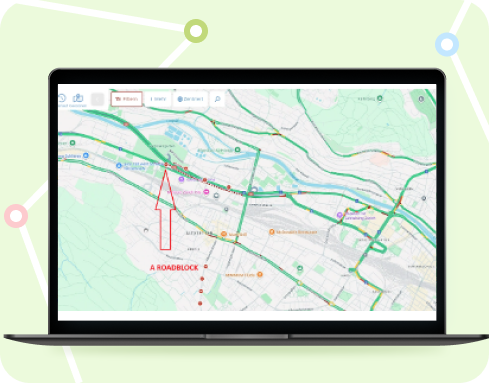

07

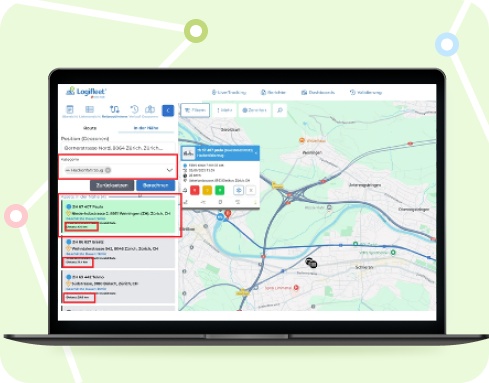

Instant Visibility with the Live Map

With Logifleet360°, David uses the Live Map to see which trucks are free, the Proximity Search to find the closest vehicle to the next job, and the Journey Optimizer to choose the most efficient route.

08

Data That Drives Decisions

At the end of the day, David reviews the Journey Report to measure kilometers driven, time spent at each stop, and cost per delivery. This data flows seamlessly into the company’s accounting or ERP system, ensuring precise reporting and better long-term planning.

09

One Screen. Maximum Efficiency.

From dumpsters to mixers, from heavy machinery to general freight - Logifleet360° unites all construction logistics into one real-time planning hub.

No more juggling spreadsheets, phone calls, and disconnected tools.

Every vehicle, every site, every delivery - visible in real time.

Every kilometer generates value.

Trusted by 500+ customers across Switzerland with mixed construction fleets across many job sites:

Join 500+ profitable construction companies in Switzerland using Logifleet

700+

20+

14 800

18 000+

8000+

Curious to see how Logifleet can help your company reduce downtime and increase productivity?

- Book a free consultation with one of our experts

- See how we can fix your data tracking problems

- Get a free quote and see the Logifleet platform in action

En Budron H9

CH-1052 Le Mont s / Lausanne

T +41 21 651 06 51

Merkurstrasse 25

CH-8400 Winterthur

T +41 71 277 52 47